How To Troubleshoot A Power Screed: The Complete Guide

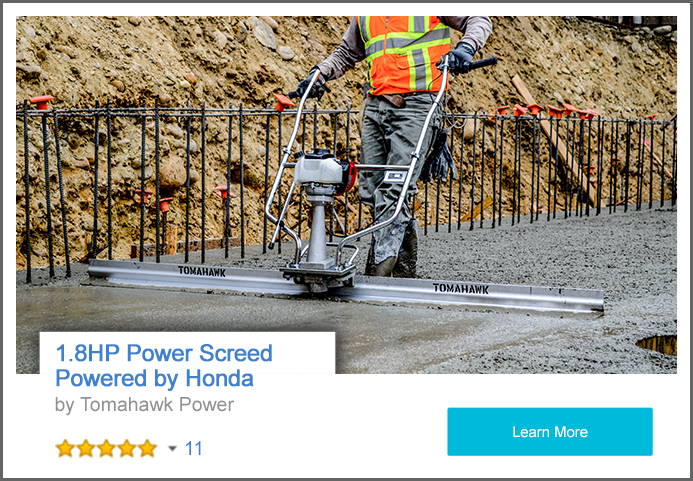

Achieve optimal concrete finishing results with Tomahawk Power Screeds. Simple to operate and with a low maintenance design, Work up to 4X Faster than traditional methods, while saving more than 75% in labor costs to help you increase project profit and crew efficiency.

If your screed begins to have problems, there are various ways to troubleshoot the unit.

We will guide you through a few quick maintenance tips to help you repair common power screed issues:

Power Screed engine is running poorly or not at all.

- Ensure the operator has completed the starting procedures found in the Operations Manual correctly.

- Check the throttle:

- How To Replace The Carburetor On A Power Screed

- Check the clutch:

- How To Replace The Clutch On A TVSA-T Power Screed

- How To Replace The Clutch On A TVSA-H Power Screed

- Check the vibrating shaft:

Assembly and Start Up

ASSEMBLY STEPS:

- Remove the unit and all pieces from the box.

- Use a socket wrench to attach the handles.

- Remove the screws attached to the handles.

- Slide the handle bars in.

- Secure the handle bars with the screws.

- Attach the kickstand using a socket wrench and given screws.

- Use a socket wrench to attach the blade.

- Bring the unit on top of the blade and align the holes.

- Insert the screws.

- Tighten each screw with the socket wrench.

START UP STEPS:

- Add 10W-30 Oil

- Add Engine Fuel

- Add Fuel Stabilizer

- Press the primer bulb until fuel can be seen.

- Push the throttle lever slightly.

- Pull the recoil starter to start the engine.

Power Screed Has A Flooded Engine

- Lean the screed back onto its handles to drain the fuel back into the tank.

How Do I Store My Power Screed For A Long Period Of Time?

- Wipe the unit down to keep it clean.

- Add fuel stabilizer to the gas tank to avoid fuel going bad. This can damage the carburetor.

- Store in a dry, cool area.

Check out our TVSA-T Troubleshooting Manual for a visual guide on this model.