One of the most vital pieces of any concrete pouring job is making sure the concrete is poured evenly and without bubbles. Screeds are used to level the concrete and remove any excess from the top. In the past, construction workers used a wooden slab to complete this part of the job, causing many issues such as injury, rapid fatigue, and long hours. Vibratory power screeds came onto the market to eliminate these problems and to get each concrete pouring job done successfully.

Here’s why a vibratory power screed is worth the investment:

Injury Prevention

According to the Occupational Safety and Health Administration, 1 in 10 construction workers is injured every year. Most of these injuries involve the worker’s back and spine. Even with proper training, some injuries are inevitable and the costs can skyrocket for companies. Often times, injuries are due to long term, strenuous labor. This happens frequently when using standard wooden screeds, as it requires the worker to be bent over for a significant period of time. Power screeds help relieve tension from the back as they remain upright during concrete finishing.

Faster Completion Time

Rather than using multiple workers to push a regular screed along freshly poured concrete, power screeds allow the job to get done with only one person, and 4 times faster than traditional concrete finishing methods. Power screeds are lightweight, which helps workers move them around the site easily. This is especially important in warmer locations, where concrete dries quickly. Faster completion times also provide workers the ability to cover large spaces efficiently. With concrete pouring and screeding being completed faster, workers can then move on to other important tasks on the job.

Professionalism

The power of professionalism wins the trust of others, whether is it with a potential client, existing client, or even potential employees. In the modern-day construction industry, it’s important to display a team that can get the job done thoroughly and on time. This is done by using equipment with state-of-the-art technology. Using a vibratory power screed boosts professionalism not only because of the design but because of the efficiency it provides for concrete finishing jobs. It is evident that using a vibratory power screed is more professional than dragging a 2x4 wooden slab along wet concrete.

Longevity of Employees

The construction industry is made up of very hard workers. But because this profession is so labor-intensive, employees are more prone to long term injury and fatigue. This causes workers to stop working earlier than those in other industries. The power screed helps reduce the labor effects that regular screeds have. Rather than bending over for each use, vibratory power screeds allow workers to stay upright. This helps them not get worn out as quickly.

Less Labor Costs

Many of the benefits listed above play into the labor costs for construction and concrete pouring companies. Fewer workers getting injured, more workers staying longer and avoiding rehiring, and faster completion all contribute to overall lower costs. Unlike a regular wooden screed, power screeds only require one person to use them. This allows companies to have fewer workers on the job, which also significantly reduces labor costs. Using vibratory power screeds can save you up to 75% in labor costs.

While the initial cost of a power screed may seem daunting, the long term benefits make it worthwhile. Many companies and workers who have power screeds say that the equipment pays for itself within one season.

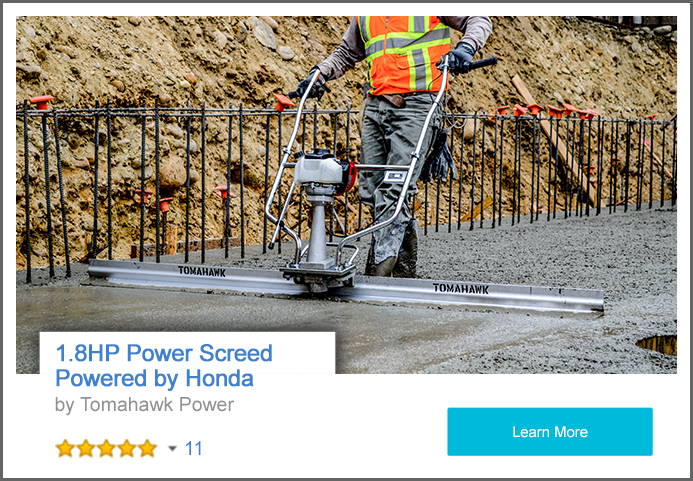

At Tomahawk Power, we are proud to provide the top power screeds in the industry. With various blade sizes and our Honda engine, our screeds can be used for any concrete pouring job.

For more tips, tricks, and insider promotions, subscribe to our newsletter.