Description

QUESTIONS & ANSWERS

Ask a Question-

Is it out of the box ready to go?

Tomahawk Power rammers need a slight adjustment to the handles before operation. Reference the quick adjustment guide to adjust the rammers handle height before starting your rammer.

-

Do you have any smaller shoe sizes?

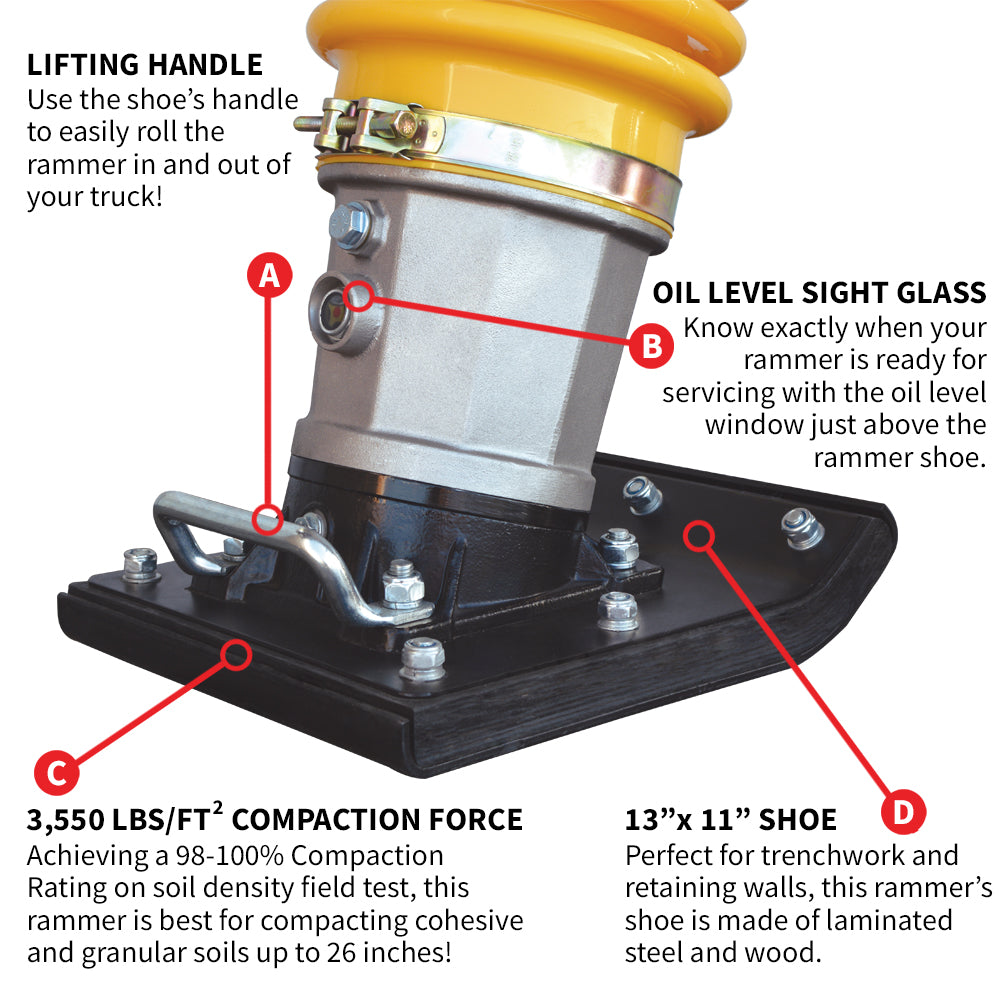

Yes, Tomahawk Power rammers have the option of a 13” x 11” shoe or a 5.5” shoe.

-

Why is my rammer leaking oil?

If you see leakage around your rammer, check the bellow and see if there is any puncture in the bellow. If so, it will need to be changed. Check the oil drain plug on the bellow and engine. Make sure it is properly tightened. Look for air gaps, and follow oil leakage to locate the problem.

-

How do I lift a tamper or rammer by myself?

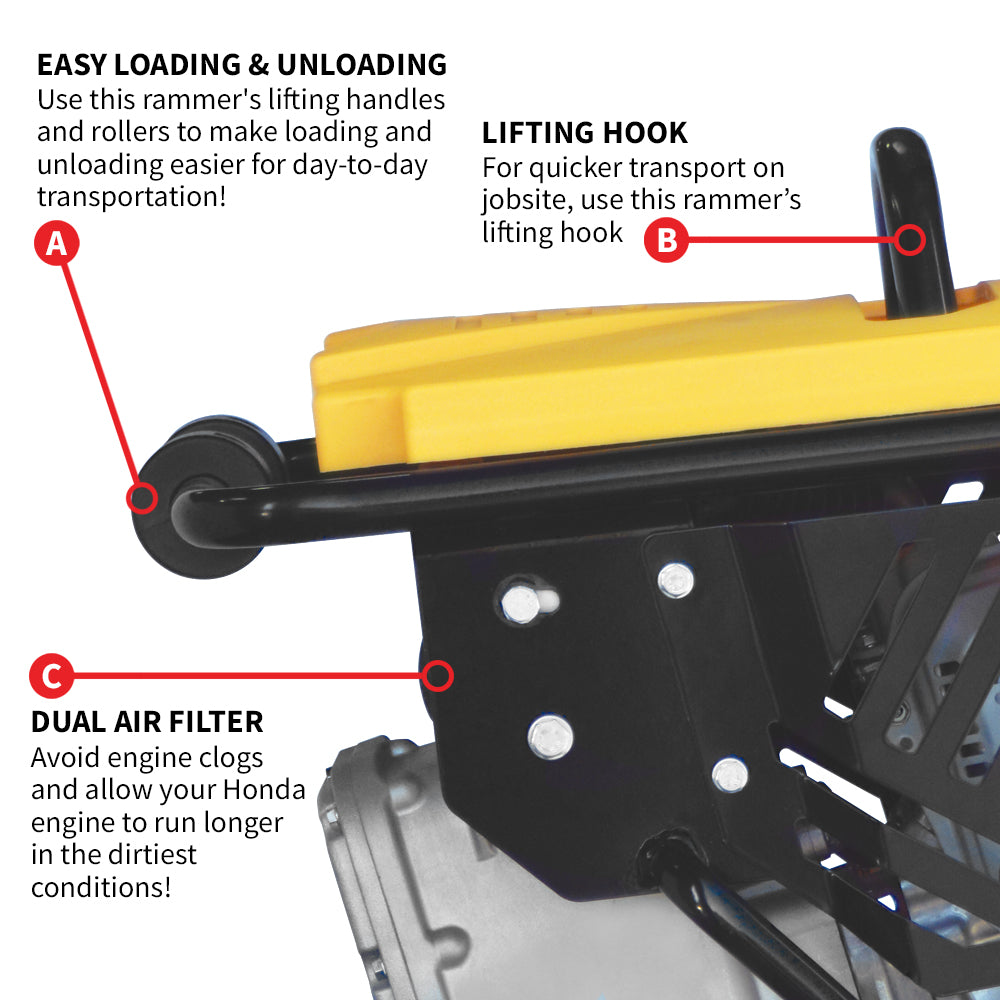

The Tomahawk TR68H rammer is designed to be lifted by one man. If you attach a wheel kit accessory, rammers can be easily maneuvered. The rammer also comes with a lifting handle near the shoe and roller mounted on the rear upper handle bar, which is designed to roll easily into a pickup truck. Heavy construction equipment may be used to lift your rammer from its top lifting hook. This can be lifted using a van or truck jib crane, which is either powered by a winch or hydraulically.

-

The rammer starts making really loud noises, what do I do?

If there is not enough lubrication in the body of the rammer, the gears will start to grind and which can be detrimental to the machine. Make sure the rammer is properly lubricated. You can do this by checking the oil level window near the shoe of the rammer. A good lubricant is SAE15W-40.

-

My rammer starts but the tamper will not run?

The rammer functions by the engine spinning a clutch. When the clutch reaches a certain revolution per minute (RPM) the rammer will engage and the gears will start, causing the rammer to jump. The first thing to check when your rammer will not jump is the clutch. If a clutch is broken it will need to be replaced.

-

Why does the rammer start but the engine die?

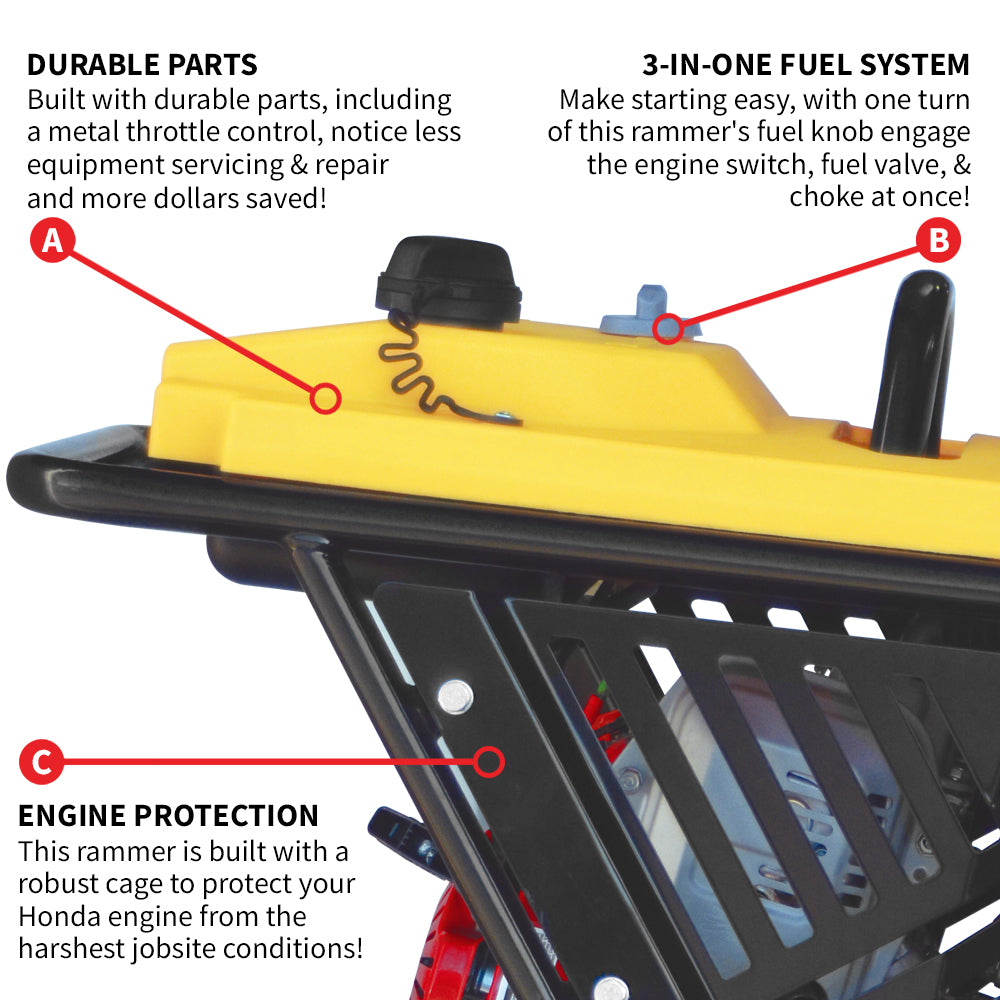

To prevent your engine troubles, make sure to use only the recommended oil and gas mixture (10W-30). Changing the oil and gas prevents buildup and clogging of the engine. Check to make sure the oil filter is clear between the gas tank and carburetor. Lastly, check to make sure the air filter is clean and free of clogs.

-

Why is my rammer or tamper engine not starting?

The first step is to always check the oil and gas and make sure that they are both sufficient. If there is not sufficient oil, the rammer will not start, which can be identified by checking the low oil sensor. Another component to check is the spark plug. If you seem to be pulling on the recoil starter many times without any results, check if the spark plug is dry and working. Check the spark plug by unscrewing the spark plug and placing it into the spark ignition coil. Pull the recoil starter several times while holding the spark plug against the metal of the engine. If you see a spark then the plug is working. If there is no spark, change the spark plug.

-

Why does my rammer not fit into the trench?

There are typically two types of vibratory rammers. The most common rammer shoe size is 11’’ x 13’’, as utilized on this rammer. The reason the shoe size is 11’’ x 13’’ is because the average trench is 1 ft wide. If a rammer shoe is more than 12’’ + typically it cannot fit into the trench. If the trench is smaller than 12’’ you might need a smaller rammer with a 5.5’’ shoe that better fits your job.

-

What kind of vibratory rammer or jumping jack do I need?

There are various types of rammers on the market. Rammers can run on a variety of engines including 2 stroke engines, 4 stroke engines, pneumatic engines, electric engines, and diesel engines. Rammers can range from 2,000 lbs per square ft to 4,000 lbs per square ft. This rammer is perfectly balanced to deliver controlled, skillful jumping motions, without causing any decline to impact force - excellent for more jobs.

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.