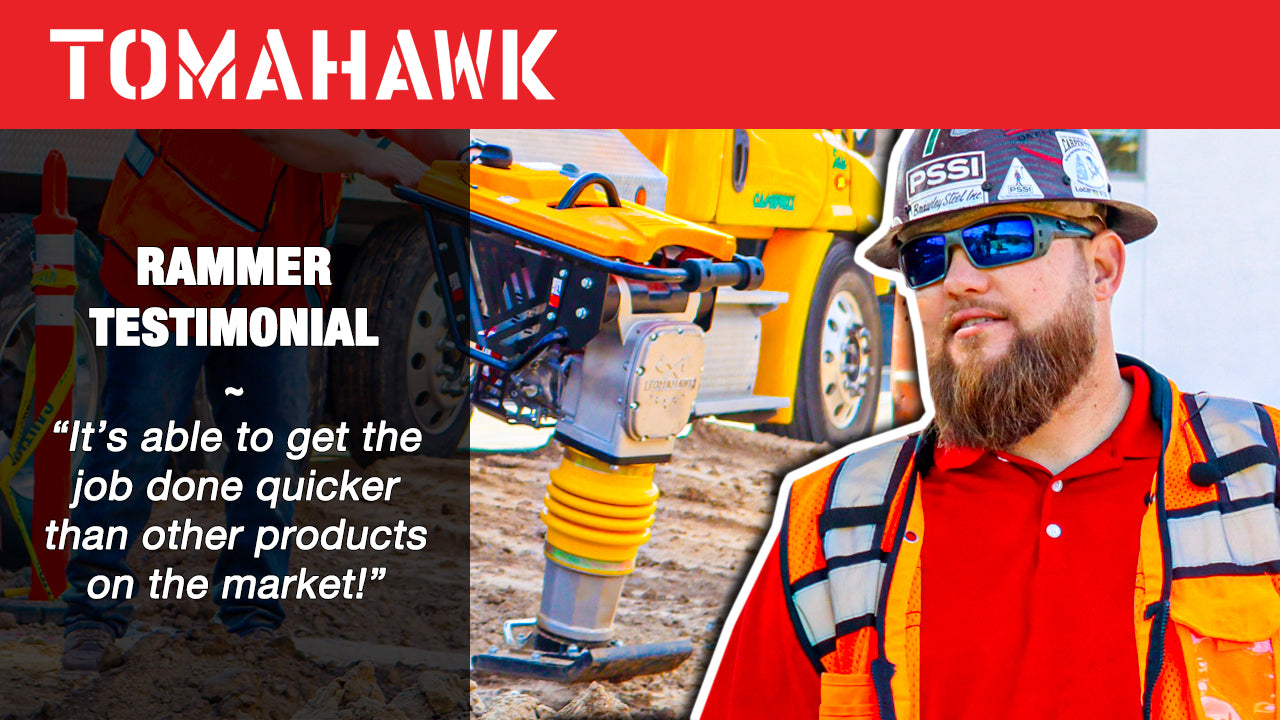

At Tomahawk Power, each piece of equipment is engineered with the operator in mind. In order to ensure that our quality meets the standards of everyday operators, we went out in the field to assess our 3.6HP Tamping Rammer powered by Honda.

We visited a San Diego business, Shelby & Sons, at one of their job sites to see first-hand the Tomahawk TR68H, and get raw insight from those who utilize and understand compaction equipment the most.

Shelby & Sons Concrete was established in 2009 by a crew of industrial concrete contractors. Their philosophy has always been based on the premise that quality begins from the foundation up.

- “From the company’s top management team to each contractor dedicated to said project, our ultimate goal is to meet or even exceed your expectations.”

We sat down with the Superintendent from Shelby & Sons Concrete, Jake Shelby, to learn about his experience using Tomahawk rammers:

What’s your name and role with Shelby & Sons?

My name’s Jake Shelby with Shelby & Sons. I am the General Superintendent.

What was your experience using the Gas Powered Honda Rammer?

In a rammer, I’m looking for speed and compaction force. I’m looking for ease of use. I’m looking for equipment that makes my job easier. Tomahawk has all of that!

Was the rammer easy to use?

The Tomahawk Rammer is very easy to use. It hits real hard and works great! With one turn of the knob you’re able to run it, plus it prevents flooding issues, so it lasts a lot longer.

The wheel kit and rollers work perfect on a job site. To have one guy wheel it around instead of hurting someone’s back and making two guys do it is great!

What type of people would benefit from a rammer like this?

I would recommend it for anybody in the construction industry. You’ve got pipeline contractors, you’ve got electricians that have to do trenching. I think they would benefit the most out of this because they have small trenches they are constantly working with and the rammer gets good compaction so you don’t have to do a bunch of passes.

Overall, my experience with the Tomahawk Rammer is it's very well balanced, and it hits real hard. It’s able to get the job done quicker than other products on the market.

We value the opinions of the everyday construction worker that uses this type of equipment day-in and day-out.

Thank you, Jake, for letting us gain valuable insight on not only our rammers specifically, but the needs and wants an operator has when performing soil compaction.