When it comes to concrete finishing, achieving a smooth, level surface is essential for the strength, durability, and appearance of any slab. Whether you're pouring industrial floors, driveways, patios, or sidewalks, using a power screed can dramatically speed up the finishing process and deliver professional-grade results.

If you're a concrete contractor—or looking to become one—understanding the fundamentals of power screeding can elevate your jobsite productivity and project quality.

In this guide, we’ll break down everything you need to know about power screeding so you can pour faster, finish better, and compete at a higher level.

What is a Power Screed?

A power screed is a lightweight machine equipped with a vibrating motor and an attached screed board (typically made of magnesium) used to smooth and level freshly poured concrete. Unlike traditional hand screeding, a power screed uses vibration to settle the concrete, removing air pockets and water for a stronger, more uniform slab.

Concrete contractors rely on power screeds to:

-

Save time compared to hand screeding

-

Reduce operator fatigue

-

Improve surface flatness and finish quality

-

Achieve more consistent compaction across large pours

Why Concrete Contractors Should Use a Power Screed

If you're still using hand tools for slab pours, you're missing out on a major efficiency upgrade. Here's why contractors across the country are making the switch to power screeds:

-

Faster Pours: Vibrating screeds cut leveling time by 50% or more compared to hand screeding.

-

Stronger Slabs: Vibrating action compacts the concrete, eliminating voids and improving long-term durability.

-

Professional Finishes: Contractors can deliver a flatter, more polished finish that reduces rework and callbacks.

-

Reduced Labor Costs: A power screed allows a smaller crew to tackle larger pours without sacrificing quality.

-

Operator Comfort: Adjustable handles and lightweight frames reduce physical strain and boost daily productivity.

For concrete contractors, time is money—and investing in the right tools like a Tomahawk power screed means finishing jobs faster and moving on to the next project sooner.

Types of Power Screeds

When choosing a power screed, concrete contractors typically have two main options:

1. Walk-Behind Vibrating Screeds

-

Best for flatwork jobs like driveways, patios, warehouse floors, and residential slabs.

-

Easy to maneuver and operate with a two-handed control system.

-

Powered by reliable gas engines like Honda GX series motors.

2. Ride-On Screeds (Less common for small to mid-size contractors)

-

Designed for extremely large pours, often seen in industrial flooring and highway projects.

-

Higher cost and complexity, typically reserved for major commercial projects.

For most concrete contractors, a walk-behind power screed offers the best balance of affordability, performance, and ease of use.

How to Use a Power Screed: Step-by-Step

Using a power screed properly is essential to achieving a smooth, professional-grade concrete finish. Whether you’re tackling a residential driveway or a large commercial slab, mastering these techniques will help ensure a faster, higher-quality job. Here's a detailed step-by-step guide:

1. Prepare and Set Your Forms

Before any concrete is poured, make sure your slab forms are:

-

Properly installed and securely braced.

-

Level and straight, using a laser or string line to double-check.

-

The correct height based on the slab thickness.

Tip: Well-set forms are critical. Your screed will ride along the surface of the concrete, not the forms, but they guide the depth and overall finish.

2. Pour and Distribute the Concrete Evenly

Start pouring the concrete across the area you plan to screed. Make sure to:

-

Avoid piling all the concrete in one spot.

-

Distribute it as evenly as possible with a rake or shovel.

-

Fill to slightly above the top of the forms, allowing for settling during vibration.

Tip: Work quickly—concrete begins to set soon after pouring.

3. Assemble and Position Your Power Screed

Prepare your screed:

-

Attach the appropriate blade size for the job.

-

Set the blade flat on the surface of the concrete at the starting edge of the pour.

-

Check that the engine is fueled, oiled, and ready to run.

Tip: Choose your blade size based on slab width; wider blades for big areas, narrower blades for tighter work.

4. Start the Engine and Engage the Vibration

Start the engine following the manufacturer's instructions:

-

For Honda engines, set the choke, pull start, and allow it to warm up.

-

Engage the throttle slowly to activate the vibration mechanism.

You'll feel the blade start to vibrate, which helps settle and compact the concrete as you move.

Tip: Always wear proper PPE (hearing protection, gloves, and safety boots) when operating the screed.

5. Screed the Surface

Begin pulling the vibrating screed across the surface:

-

Hold the handles firmly and walk slowly backward.

-

Keep the screed blade moving at a steady, even pace.

-

Let the vibration do the work—do not push down on the screed.

-

Watch the concrete in front of the blade; you should be filling any voids as you move.

Tip: Maintain a consistent angle with the blade (typically slightly tilted back toward you) for optimal leveling action.

6. Overlap Your Passes

When screeding large areas:

-

Overlap each pass by 6 to 12 inches to ensure even compaction and surface uniformity.

-

Work systematically from one side of the slab to the other.

Tip: It’s better to overlap slightly more than to leave gaps, which can create uneven finishes.

7. Monitor Surface Flatness and Consistency

As you screed:

-

Regularly check your surface for dips, ridges, or low spots.

-

Fill any depressions with fresh concrete and rescreed as needed.

-

Make adjustments on the fly by slightly altering blade tilt or pace.

Tip: Concrete contractors know that catching and correcting surface issues immediately saves hours later during floating and finishing.

8. Shut Down the Screed Properly

When you're done:

-

Reduce the throttle and turn off the engine.

-

Remove the blade from the concrete.

-

Immediately rinse off any fresh concrete to prevent build-up on the blade and engine frame.

Tip: Always clean your equipment right after use to prolong the life of your power screed.

Final Touches After Screeding

Once screeding is complete:

-

Begin bull floating immediately while the concrete is still workable.

-

Allow bleed water to rise and evaporate before starting further finishing steps like edging, jointing, or troweling.

Proper screeding sets the foundation for every subsequent finishing step—investing care at this stage pays off in a stronger, more beautiful slab.

Key Features Concrete Contractors Should Look for in a Power Screed

Choosing the right screed can make all the difference on the jobsite. Look for these features:

-

Reliable Engine: Honda GX35 or equivalent 4-stroke engines for reliable starts and low maintenance.

-

Lightweight Frame: Easy to maneuver, even on large pours.

-

Ergonomic Handles: Adjustable handles reduce strain and fatigue.

-

Interchangeable Blades: Ability to swap screed boards of different lengths depending on the project.

-

Low Vibration Handles: Minimize operator fatigue for all-day comfort.

Tomahawk power screeds are specifically engineered with these contractor-friendly features in mind.

Choosing the Right Blade Size

Blade size matters. Here's a general guide for contractors:

-

4' to 8' Blades: Best for smaller projects like patios, walkways, and driveways.

-

10' to 12' Blades: Ideal for mid-size residential pours like garage slabs or small commercial floors.

-

12'+ Blades: Perfect for large commercial pours, parking decks, and warehouse floors.

Selecting the right blade width allows concrete contractors to maximize productivity without overworking the machine—or themselves.

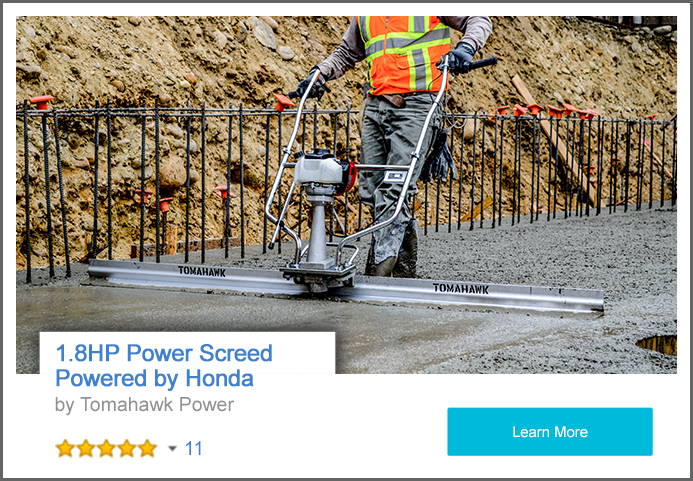

Top Benefits of Tomahawk Power Screeds

-

Durable Magnesium Blades – 30% lighter than aluminum for easy handling.

-

Honda-Powered Performance – Dependable engines built for tough jobsites.

-

Fast Setup and Operation – Get working within minutes of arrival on-site.

-

Nationwide Service Support – Access to repair centers and parts wherever your jobs take you.

Tomahawk Power Screeds are trusted by concrete contractors, flatwork specialists, and general contractors across North America for one reason: they work hard, just like you.

Ready to Upgrade Your Finishing Game?

If you're ready to take your concrete pours to the next level, investing in a Tomahawk Power Screed is a smart move. Whether you're pouring driveways, garage floors, sidewalks, or slabs, you'll see faster, flatter, and more professional results.

Power through your next jobsite with Tomahawk!