Proper concrete vibration is a critical part of the construction of any concrete foundation, wall, column, beam, or slab. Concrete contractors use several types of equipment to ensure that concrete structures are built to specifications. Why does concrete need to be vibrated? It is to ensure structural integrity by eliminating air pockets and cold joints of a concrete structure. Cold joints are when a new layer of concrete is poured over an older layer, and the 2 different pours do not properly mix, or bond to each other. This can create unwanted gaps in the concrete layers, and can greatly affect the longevity and safety of a newly built structure. These air pockets and cold joints can be prevented by using high frequency vibration that is delivered by several different types of products. Different concrete vibration products are used in different circumstances. These different products are listed below.

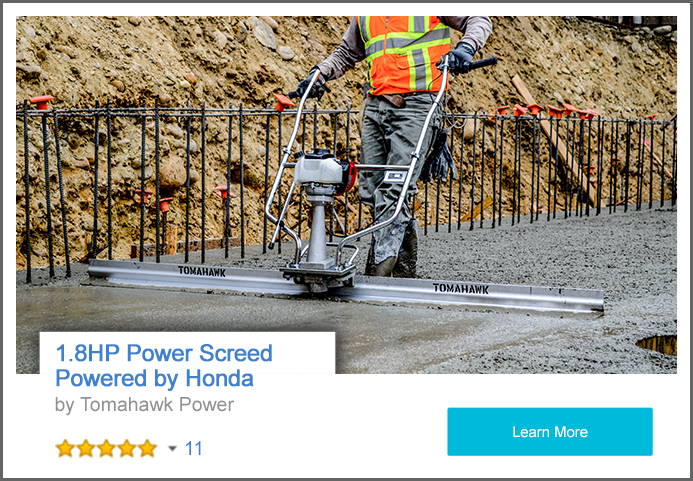

Surface vibration equipment is often used for concrete pours of less than 6 inches. Examples of this equipment would be a concrete power screed. Tomahawk Power screeds are used for both smoothing out the surface of a concrete pour, while simultaneously delivering vibration through a gas powered engine. The Tomahawk power screed comes in options for both 8 and 12 feet. This is often used on smaller concrete slabs or some concrete side walk work.

Internal concrete vibrators are some of the most commonly used concrete vibration equipment. Tomahawk Power’s TVIB3 features a 2 horse power electric motor that can deliver up to 15,000 vibrations per minute. Internal concrete vibrators are run by a single operator, and the motor connects to a hose with a flexible shaft, that can be dipped vertically into newly poured concrete to deliver the vibration. The general rule for how long to keep the head of the concrete vibrator shaft in the concrete is to insert the head fully, and then remove the head about 1 inch per second. The Tomahawk Power TVIB3 has a 8.3 inch head, that varies between 1-2 inches, with the standard size at 1 and ¼ inch. There are also 3 different options for the TVIB3 hose lengths. The options are 7, 10, and 17 feet length hoses. Depending on the type of job, a contractor may require a greater length of the flexible shaft in order to properly reach the freshly poured concrete.

When operating a TVIB3, for optimal vibration results, it is recommended to insert the head fully, and then pull up at a rate of 1 inch per second, and no quicker than 3 inches per second. While operating this equipment, it should be apparent once all of the air bubbles stop surfacing, and you can move on to the next dip of the concrete vibrator. All concrete vibrators have a radius in which the vibration is being sufficiently delivered. As a general rule, the large the concrete vibrator head, the larger the radius is. While operating the equipment, it is important for each radius to overlap, to avoid any missed areas where air bubbles may still exist. The Tomahawk Power TVIB3 has a radial range of 6-32 inches depending on the size of the concrete vibrator head.