At the end of 2018, Atlanta will be the 3rd fastest growing major metropolitan area in the United States – beaten only by the Dallas, TX (1st), and Houston, TX (2nd) metro areas. With the rapid increase in population growth, this puts additional strains on the local construction industry to keep pace with new residents’ needs. Many of these new residents are looking to move to neighborhoods such as Midtown, where over 2,400 apartments are being built, with thousands more in the proposal stage. In fact, over 30 major construction projects are underway in just the Midtown district, in an effort to catch up to the new boom in recent population growth.

This type of development has obvious implications for both local construction contractors and local construction supply companies. Every link in the construction supply chain is critical to effectively deliver quality results to demanding customers, in this case, a new wave of Atlantans. Contractors need a variety of equipment: compaction, concrete cutting, concrete spraying and finishing, portable generators, raw construction materials, and personal safety gear to effectively deliver on the many bids they submitted months, sometimes even years, in the past.

Construction supply companies are communicating to manufacturers like Tomahawk Power their own needs and yearly order projections for compaction, concrete cutting, concrete finishing, and portable generator equipment. Concrete and asphalt plants are running around the clock to be able to deliver to the hundreds of job sites around Atlanta with construction crews eagerly waiting to get to work. City construction teams and engineers are communicating to local police, residents, local utility companies, and construction contractors alike to make sure that interference with normal day to day activities throughout the greater Atlanta area are kept to a minimum. With so much chaos and time demands on each link in the supply chain in order to deliver a project on schedule and within budget, it is sometimes easy to overlook the basics of proper concrete construction.

Those outside of the construction industry often take for granted the modern marvel of current concrete construction techniques. Concrete is one of the most widely used and recognizable construction materials known to man, and yet, its abundance and versatility often go unnoticed. The basic raw materials of 3000 PSI concrete are: 1 part cement, 3 parts sand, and 3 parts aggregate (stone). This strength of this mix can vary greatly however, depending on how much water you add into it. The general rule is that the more water you add, the weaker the overall strength of the concrete will be. Every project is unique, and has its own requirements, but contractors need much more than a proper concrete mix to avoid long term issues with a concrete pour.

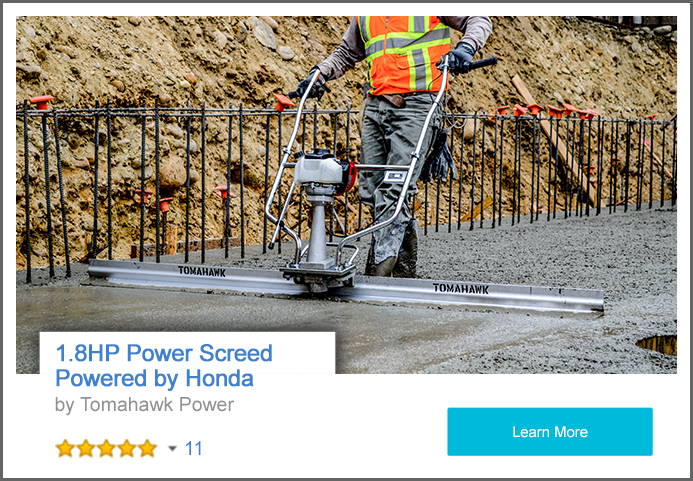

To ensure proper concrete pouring practices, construction crews and city officials in Atlanta should consider several variables other than water. For example, at the time of the concrete pour, what is the ambient temperature? How many air pockets were left hidden in the concrete because the proper tools such as a concrete vibrator were not utilized to eliminate them? Was the proper concrete sprayer used to finish the concrete with the correct curing compound, to avoid excessive evaporation levels? Tomahawk Power concrete sprayers, concrete vibrators, and high quality finishing screed and trowel equipment are ideal to ensure these questions are answered in a way that don’t require a concrete crew to redo their work. Apart from eliminating surface level impurities in the concrete, concrete finishing screeds also ensure a highly smooth and professional finish to any concrete pour. In 2019 Tomahawk Power will introduce the first of its kind, a 2-stroke engine, gas powered backpack concrete sprayer. Unlike manual pump sprayers, the TPS25C concrete sprayer has consistent pressure, meaning that spotty spraying can be avoided, which damages the integrity of the concrete pour. Manual pumps are also more cumbersome to use, as they require pumping every few seconds, while the Tomahawk Power TPS25C concrete sprayer doesn’t require any pumping at all.

The greater Atlanta metropolitan area is expected to continue to grow in population throughout 2019, and unless these new residents want to be living in shoddily built structures, contractors and city officials alike need to be sure to use proper concrete equipment that won’t leave anything to chance.