Concrete is quite a versatile material. It is used for small projects like patios and pool decks and even larger skyscraper builds. It can provide long-lasting strength. It lasts longer than almost any other material out there, especially concrete flooring.

Concrete sealers, retardants, forming oils, etc. are used for protecting concrete and elongating its life. We will be discussing these today.

Concrete Sealant

A concrete sealant protects concrete from water. It blocks the pores in concrete so that water cannot be absorbed into the concrete. It forms an impermeable layer that reduces the absorption of water and other substances that can damage the concrete. There are two categories of sealers primarily.

1) Topical Sealers

Concrete must be clean and dry to apply topical sealers. It helps with adhesion and thus lasts longer. It can protect concrete from chemicals and stains. It also enhances the appearance of the surface. It can last from 1 to 5 years.

2) Penetrating Sealers

The surface should be dry or damp with matching porosity in order to achieve adhesion. Its lifespan is more than 5 years.

Curing Agents

The concrete curing process simply evaporates water within the concrete. The water should evaporate and slowly and gradually. Water will still be present further down the slab if it evaporates quickly. It will only dry up from the surface which will cause problems later. That slab might not be able to withstand heavy weights because it might be weaker in its depths. Cracks may appear over time.

Uring agents form a protective layer on the surface of a concrete slab while it cures. It helps to prevent cracks and dust by not allowing water to evaporate quickly.

Concrete Retardants/Top Cast

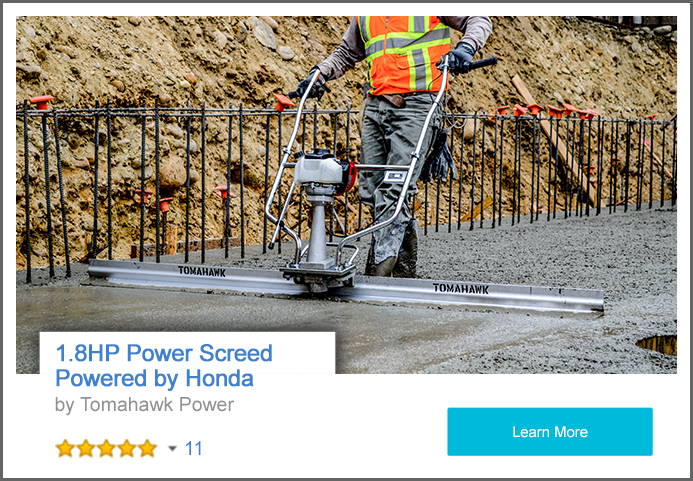

Retarders and surface retarders can help you achieve an architectural finish to our concrete. This chemical agent slows down the chemical reaction in concrete to slow hardening process. It is sprayed on top of fresh concrete after screeding. The top layer including the retarder will be power washed off to reveal the underlying aggregate for a decorative concrete finish.

Forming Oil

Concrete Forming Oils are a mixture of mineral oils and specialized release agents which are spraying on top of concrete to create a barrier and prevent concrete for adhering to metal or wooden forms. Forming Oils can be applied with brushes or with concrete sprayers.

Conclusion

There are many different solutions and agents that can been used to help achieve your desired concrete finish. From sealants to forming oils, it is important to understand the chemicals available to execute and elevate your concrete finishing work.