What is Concrete

One of the most commonly used construction materials, concrete is an amalgamation of cement, water, and finely coarse aggregate in the form of sand, gravel, or rock. It is used to build large structures, buildings, patios, roads, bridges, dams, and more. It can be easily cast or molded into any shape.

Benefits of Concrete

Due to its flexibility, concrete can be used in different fields and comes with various benefits, such as:

- It is durable, sturdy, and therefore, can be used for long-term commercial projects and underground utilities as well.

- It is economical and cost-effective in comparison to other similar construction products in the market, such as asphalt.

- It can withstand even high temperatures and extreme weather conditions.

- It is inert and fire-resistant.

- When concrete is freshly prepared and mixed, it can be easily molded into any shape.

- It requires very little maintenance and can be easily sealed or refurbished with the help of a concrete sealant.

- Its strength and sustainability increase over time.

- It is flexible and can be used as a foundation for various structural projects.

|

Drawbacks of Concrete

Along with the many benefits, there are also drawbacks to using concrete. Some of them are:

- If a cheap version of portland cement is used during the production of concrete, it can easily get desegregated when coming in contact with alkalies.

- It requires constant and regular reinforcement to avoid the risk of getting cracks.

- It can easily split and rupture under extreme cold weather conditions and low temperatures.

- The restoration process of a structure made out of concrete requires more labor and force, in comparison to other similar materials.

- It has a low tensile strength.

How to Maintain Concrete

It is important to maintain concrete regularly, to minimize the risk of cracks or trip hazards. Here are a few tips:

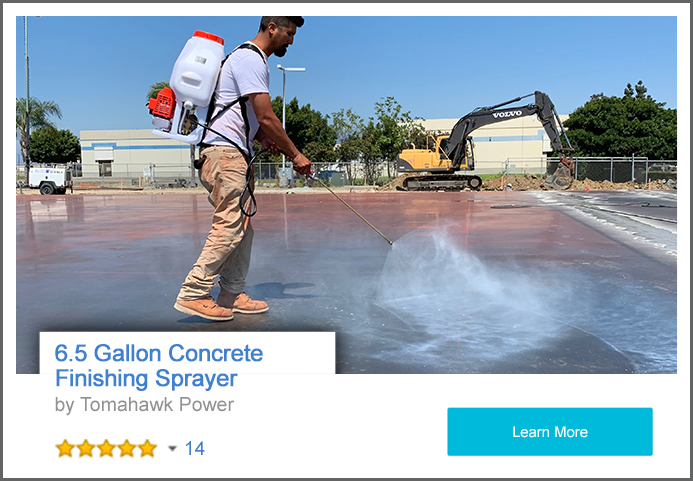

- After pouring the concrete, spray a sealant on the concrete to keep it water tight. This can add many years to the lifespan of the concrete.

- Cut joints into the concrete to reduce serious stress crack throughout the whole slab.

- Harsh chemicals and fertilizers should be refrained from using on the concrete material.

- Cracks and breaks formed on the concrete should be immediately taken care of to avoid fluid from seeping through the cracks.

Conclusion

Even though concrete is reasonably easy to maintain, the manufacturing, pouring, and sealing of concrete is important to maintaining a longer lifespan.

1 comment

Levi Armstrong

It’s good to know that concrete is an excellent construction material since it’s doesn’t need much maintenance, durable, and economical. My dad plans on having an office space constructed downtown soon. I’ll note this information you said and share it with Dad tonight. Thanks. https://www.sita-enterprises.com/concrete-services