The foundation of any successful construction project lies in proper preparation. When it comes to concrete slab construction, achieving a level and smooth surface is paramount. Power screeds have emerged as essential tools in the realm of concrete slab preparation, revolutionizing the way slabs are poured and finished. This blog delves into the significance of power screeds in the process of concrete slab preparation and explores how they contribute to elevated results in construction.

1. The Power of Precision

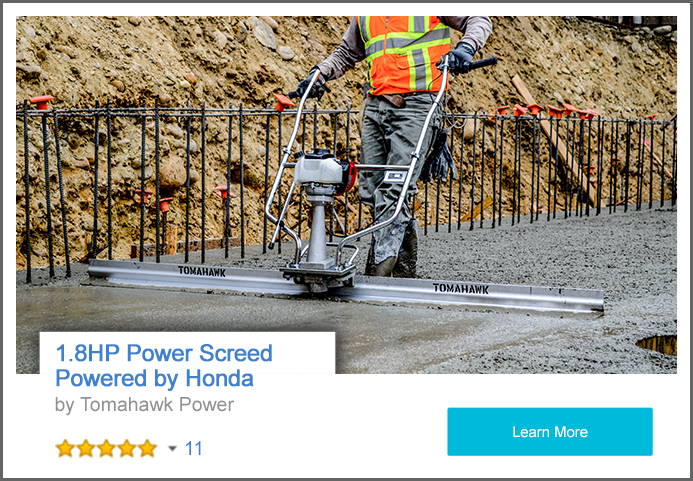

Power screeds, also known as vibrating screeds, are mechanical devices designed to ensure an even and level surface during concrete slab preparation. These tools consist of a vibrating blade that is guided across the wet concrete, distributing it uniformly and removing excess air. The precision and efficiency of power screeds play a critical role in achieving a solid foundation for the construction project.

2. Establishing a Level Base

The primary objective of power screeds in concrete slab preparation is to establish a level base. A level surface ensures that the concrete slab will be uniform in thickness, which is crucial for the structural integrity of the finished project. Unevenness or slopes can lead to structural issues and compromise the quality of the slab.

3. Enhancing Compaction

Proper compaction is vital for the durability and longevity of concrete slabs. Power screeds excel in enhancing compaction by vibrating the wet concrete, removing air pockets and voids. This compaction results in a denser and more robust slab that is less susceptible to settling and cracking over time.

4. Time and Labor Savings

Before the advent of power screeds, achieving a level concrete slab required significant manual labor and the use of traditional screeding tools. Power screeds have revolutionized the process by mechanizing the leveling and compaction steps. This mechanization not only reduces the physical effort required but also saves time, leading to increased efficiency and cost savings.

5. Consistency in Thickness

Power screeds ensure that the concrete slab is poured at a consistent thickness throughout. This consistency is essential for load-bearing capacity and uniform weight distribution. A well-prepared and evenly distributed slab foundation is less prone to settling, leading to a more stable and reliable finished structure.

6. Minimizing Re-Work

The precision and accuracy of power screeds minimize the need for re-work and corrections after the concrete has been poured. A properly prepared slab foundation reduces the likelihood of unevenness, slopes, or depressions that would otherwise require additional work to rectify.

7. Versatility in Applications

Power screeds are versatile tools suitable for various concrete slab projects. Whether it's a residential driveway, a commercial floor, or an industrial pavement, power screeds ensure that the concrete slab is prepared to the highest standards of quality and precision.

8. Expert Results for All Skill Levels

While power screeds deliver expert-level results, they are designed to be user-friendly and accessible to operators of all skill levels. The ease of operation and straightforward controls empower both seasoned professionals and those new to the construction industry to achieve exceptional results.

Concrete slab preparation is the foundation on which construction projects are built. Power screeds play a pivotal role in achieving level, even, and compacted surfaces that form the basis of successful structures. By enhancing precision, efficiency, and consistency, power screeds contribute to elevated results in construction, ensuring that the finished project stands the test of time. From leveling the ground to paving the way for excellence, power screeds are transformative tools that exemplify the synergy of technology and craftsmanship in the world of construction.