Stress cracks are a natural result of aging concrete, however you can prepare your concrete for eventual cracking by cutting control joints. Creating these control joints depends on quite a few factors, including concrete admixtures and air temperature.

When to Cut Fresh Concrete

Cutting concrete too early can cause raveling, an effect that is created by the saw blade pulling aggregate of of place. This leaves an messy cut and can damage the concrete saw's blade. Cutting concrete too late will allow concrete time develop uncontrolled cracks as the concrete is expands and contracts during curing.

Cutting concrete at just the right time will depend on the air temperature. In hotter weather conditions, concrete cutting may begin within four hours of the concrete being poured. In cooler weather conditions, concrete cutting may begin within twelve hours of the concrete being poured. Testing the concrete with trial cuts is a great process to determine when to begin cutting control joints. Making trial cuts after 30 minutes, after the concrete can be walked on, until the raveling stops is great method to test your concrete.

Where to Cut Fresh Concrete

While the concrete is setting, take the time to determine where you will be making the joint cuts. It is recommended to start these cuts from the center of column lines. Joints are recommend to be spaced out between 24 to 36 times the slab thickness - meaning if your slab is 6 inches thick your joints should be 144 to 216 inches apart (12 ft to 18 ft). If you know your concrete mixture has a high shrink rating, you may want to choose joint spacing on the lower end of this scale. Before making any cuts, make sure to confirm the spacing with your structural engineer.

NOTE: Try to choose areas that do not have steel reinforcement that continues from one slab into another.

How to Cut Fresh Concrete

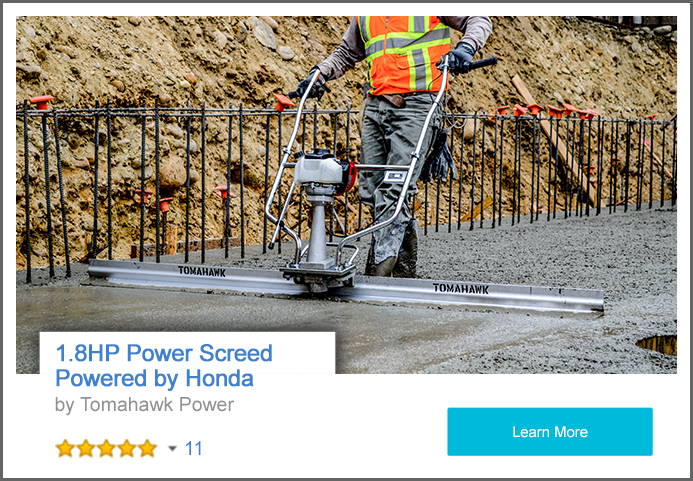

As explained previously, factors such as air temperature, concrete mixture, slab thickness, and slab length should all be considered before cutting slab joints. Once you have determined where your joints will be, begin to mark the concrete with chalk. Make your lines as straight at possible, as saw cuts should be continuous and should not cause the blade to twist. Use a green concrete saw to make your cuts, as they are excellent for making straight cuts. Additionally, their light weight design and polyurethane wheels will not damage your concrete while walking the saw over the concrete. Your cuts should be made between 1/4x to 1/3x the slab thickness. So, a slab of 6 inches should have joint cuts made at a depth of 1.5" to 2".

NOTE: Do not let the saw's blade continue to spin in its cut as this will increase wear on the bond.

3 comments

Angela Waterford

I appreciate your explanation on cutting fresh concrete and that determining the right time to cut it will be dependent on the air temperature. Thanks for reminding me to make sure that I choose a slab of concrete to cut that is not connected to any steel reinforcements. Learning how to cut concrete sounds complicated so I think it might be cost-efficient to contact a professional who already has the necessary equipment to do it along with their expertise instead of attempting to do it on your own. https://www.greenesinc.com/concrete-cutting-services

Anna Davis

Thanks for explaining that you should consider factors like slab thickness and air temperature when cutting concrete. My back patio is at least 30 years old and is full of cracks, so I am thinking about having it removed and replaced. The information you shared will be good to know throughout this process. http://cramcrete.com/concrete-cutting-services

Taylor Hansen

It really helped when you said that joints are spaced out 24 times the slab thickness. I need to have my concrete cut up by my front door since it looks really bad. I’ll be sure to hire a professional so I don’t mess anything up. https://concretecutouts.com/concrete-cutting