Sidewalks and walkways are essential to any development and should be built by following the right procedures. The whole process begins with excavation and is followed by soil compaction, in preparation for the concrete pour. Concrete screeding is carried out immediately followed by concrete troweling and concrete spraying. You will find that in preparation for your concrete pour, the right crew, weather conditions, proper compaction equipment, and concrete finishing equipment will be fundamental to making sure your concrete pour goes off without a hitch!

How to Build a Concrete Sidewalk

Once the area that will soon be your concrete sidewalk is excavated, soil compaction and overall conditioning of the soil is your next step. Efficient, reliable, and effective compaction equipment is extremely necessary for the foundation and base of your concrete sidewalk. There are numerous factors that need to be considered before choosing the right compaction equipment for your project. The application of the equipment needs to be considered. The size and the depth of the area where the compaction needs to be carried out also matters. The space allocated for the concrete sidewalk will play a key role in choosing the type of compaction equipment that is to be chosen. The soil type and density of the ground should also be taken under consideration.

Choosing the Right Compactor

Typically, for concrete slabs, sidewalks, and pathways, a plate compactor is the appropriate tool for soil compaction. For most professional concrete sidewalk project meant for public use a heavier plate compactor will be needed. Weight is an important factor when choosing a plate compactor, because it corresponds to the compaction force tamping the soil. Plate compactors ranging from 175 lbs to 210 lbs are a great size for preparing the base for a sidewalk. In this range, look for a compactor that can deliver a compaction force between 3,000 – 3,500 lbs per square foot.

Your compactor should also have a reliable engine. Compactors powered by Honda or Kohler engines are very reliable and typically never have an issue starting or compacting soils. If there was an issue, these engines are very common, and even the oldest rental Honda engine has replacement parts readily available with your local engine shop around the corner to fix it in no time at all. If you do not recognize the name of the engine, it is probably best to remove the model from your list and keep looking.

The Concrete Pour

The largest challenge of building your concrete sidewalk or pathway is the concrete itself. Not only is the blend of concrete important, but how it will react once poured in your external weather conditions. You can most definitely pour the concrete within a widespread temperature range, but it is best to try to pour in temperate weather. Hot weather can quicken concrete finishing and cold weather can delay it and even ruin your concrete slab. Rain also will completely ruin the finishing of your concrete. Make sure to monitor the weather before you schedule your concrete pour. If the weather is not on your side, you will need to plan to make adjustments to the size of your crew, equipment, evaporative retarders and/or concrete blankets you plan to use to make sure your concrete pour is not ruined.

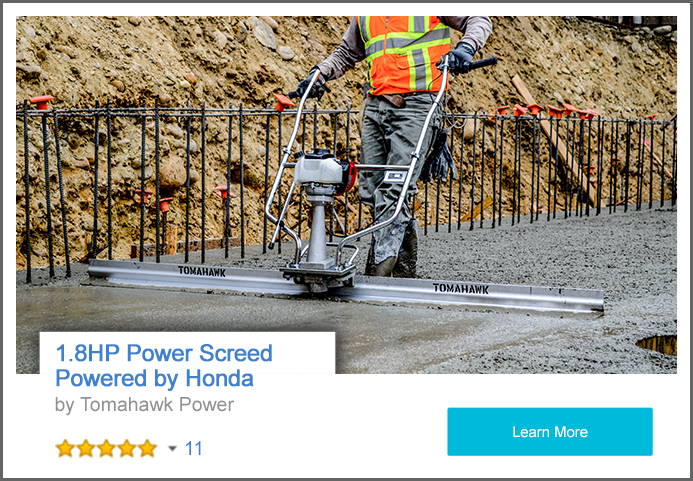

While you are pouring the concrete you need to make sure that your crew is actively leveling the surface of the concrete sidewalk and moving the concrete around evenly. This can be accomplished with shovels as well as power screeds and/or 2x4 beams to pull the concrete evenly across your sidewalk area and strike off at the forms. It is extremely important that your crew vibrate the concrete with either an electric or gas powered concrete vibrator. This will remove air pocket hidden in the concrete that can ruin the integrity of your concrete sidewalk. Once this is done, you can focus your efforts on smoothing the concrete with bull floats and trowels. Once the concrete is firm enough to stand on, but not completely set, brooms and other accessories may be used to give a brushed look to the concrete.

Concrete Joints and Sealing

Next you will need to cut stress joints in your concrete. You can use an electric saw or walk behind early entry saw to make these cuts. Concrete naturally expands and contracts as the outside temperature gets hotter and colder. This movement is causes the concrete to crack. You cannot avoid this cracking, but with the addition of stress joints, you can focus the natural cracking towards a pre-made cut, to maintain the integrity and appearance of your finished concrete for years to come.

Finally, you will need to spray your concrete with a sealant. Sealing the concrete will help protect your project and shield the concrete from external elements such as rain or snow. You may use either a manual sprayer or a power sprayer to complete this task. Keep in mind, this routine is often overlooked and completely poorly due to the combination of the crew being exhausted from a long day and inadequate equipment.

Manual sprayers, often used in concrete finishing, are tedious to pump and normally have an inconsistent spray pattern due to their nature of losing pressure. Power concrete sprayers are great for maintaining pressure, which provides an even coat of sealant, while cutting spray times significantly. This is very important when you are dealing with hotter weather that will set your concrete faster. As a rule of thumb gas powered concrete sprayers can finish 15,000 square feet of concrete in about 10 minutes, whereas a manual pump sprayer can cover the same distance in 1.5 hours. In the long term, the results of using a power concrete sprayer vs a manual sprayer will be night and day. Inconsistent spraying will lead to quicker concrete deterioration and eventual need for replacement.

Once sealed up, your new concrete sidewalk will be ready for the public after 24-48 hours (depending on your weather conditions and concrete sealing products). If you are in need of the right concrete finishing and compaction equipment for your upcoming concrete sidewalk project, look no further than Tomahawk Power for your concrete solutions!