In busy warehouse environments, small moments of confusion can lead to big delays. Searching for inventory, misplacing materials, or routing items incorrectly all cost time and increase error rates. One of the simplest and most effective ways to eliminate these issues is through well-designed labeling systems.

For warehouse managers, labeling isn’t just about identification—it’s about creating visual clarity that supports organization, improves material handling, and maximizes available space.

Create Instant Clarity Across the Warehouse

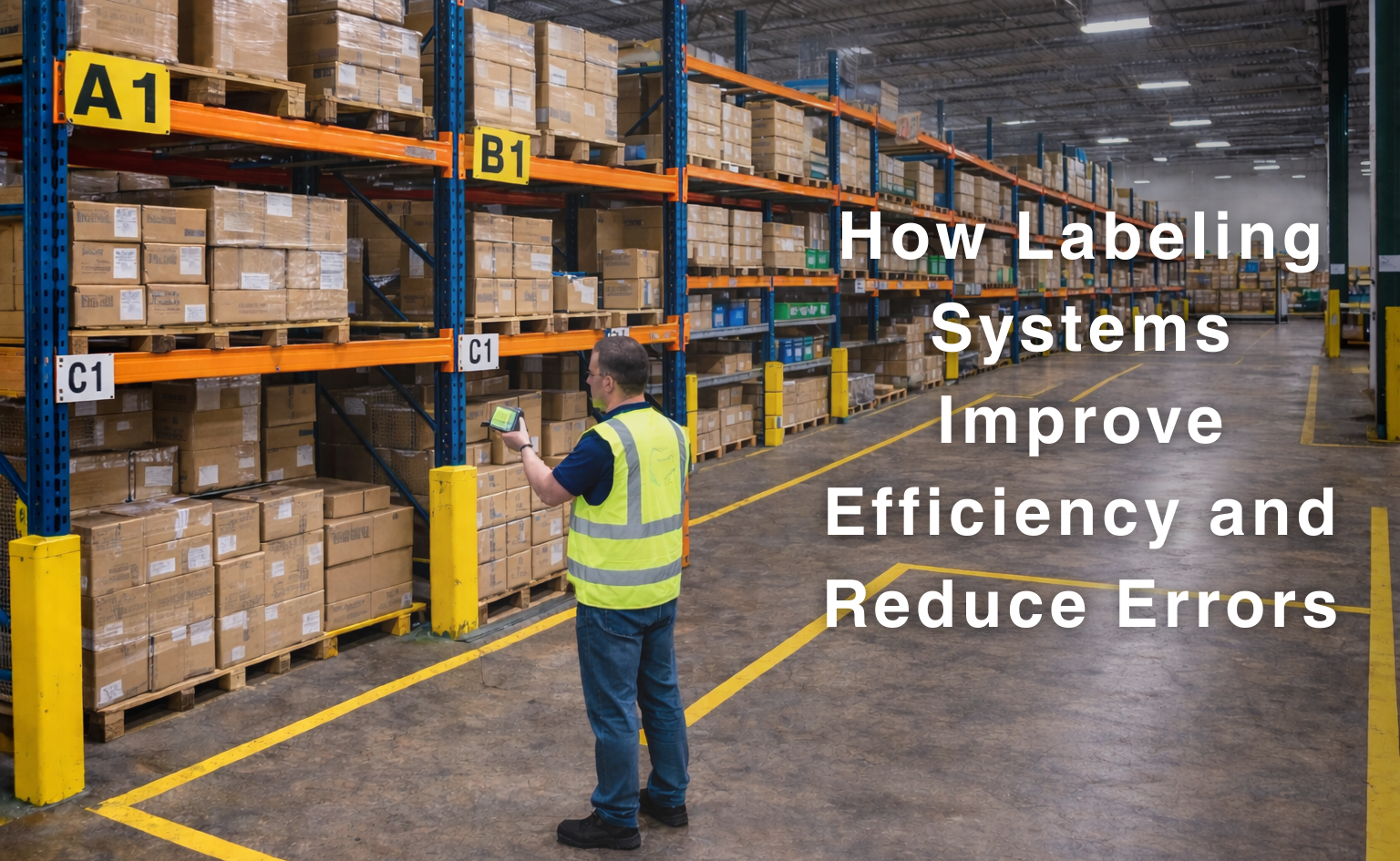

Clear, consistent labeling allows workers to identify locations, inventory, and equipment at a glance. When shelving, racks, and storage zones are properly labeled, employees spend less time stopping to confirm where items belong.

Labeling systems are especially effective in large warehouses where teams rely on visual cues to move quickly. When paired with organized layouts, labeling reduces decision-making time and keeps workflows moving smoothly.

Improve Accuracy in Picking and Replenishment

Labeling plays a critical role in reducing picking and replenishment errors. Clearly marked rack locations, bin numbers, and pallet positions help workers select the correct items without hesitation.

When materials are transported using utility carts or electric transport equipment, accurate labeling ensures items are delivered to the right zone every time. This reduces rework and prevents inventory from ending up in the wrong location.

Support Better Space Utilization

Efficient labeling helps warehouse managers make better use of space. When every rack level, aisle, and storage zone is clearly identified, inventory placement becomes more intentional.

Labeling supports vertical storage by making upper rack locations easy to reference and manage. This keeps floor space open for material handling equipment such as carts and electric utility vehicles, improving overall traffic flow.

Strengthen Equipment Organization

Labeling isn’t limited to inventory. Equipment storage areas benefit just as much from clear identification. Labeling parking zones for carts, wheelbarrows, and electric equipment helps keep tools from drifting across the warehouse.

When equipment has a clearly labeled home, teams return tools consistently, reducing clutter and preserving aisle space. Durable material handling equipment that’s easy to maneuver and store supports this system naturally.

Enhance Training and Onboarding

New employees learn faster in well-labeled environments. Clear labels reduce reliance on verbal instructions and minimize mistakes during early shifts.

Labeling systems provide a visual guide that reinforces training, helping new hires understand warehouse layouts, storage rules, and equipment placement without slowing down experienced teams.

Maintain Label Visibility With Clean, Organized Floors

Labeling systems only work when they remain visible. Dust, debris, and worn floor markings can reduce their effectiveness over time.

Regular floor cleaning helps preserve label visibility and improves safety. Industrial push sweepers and ride-on sweepers are effective tools for maintaining clean aisles and storage areas without interrupting daily operations.

Effective labeling systems do more than identify—they streamline how a warehouse functions. By improving organization, reducing handling errors, and supporting efficient use of space, labeling helps warehouse managers maintain control in fast-moving environments.

When combined with dependable material handling tools—such as utility carts, electric transport equipment, and industrial floor-cleaning solutions—labeling systems become a powerful foundation for long-term efficiency. The result is a warehouse that operates with greater accuracy, speed, and confidence.