In the realm of construction, precision is paramount. When it comes to concrete placement, achieving a level and smooth surface is essential for the integrity and aesthetics of the final product. Power screeds have emerged as indispensable tools in the journey from freshly poured concrete to a perfectly finished surface. This blog delves into the significance of power screeds in the process of concrete placement and explores how they contribute to achieving perfection in construction.

1. Understanding Power Screeds

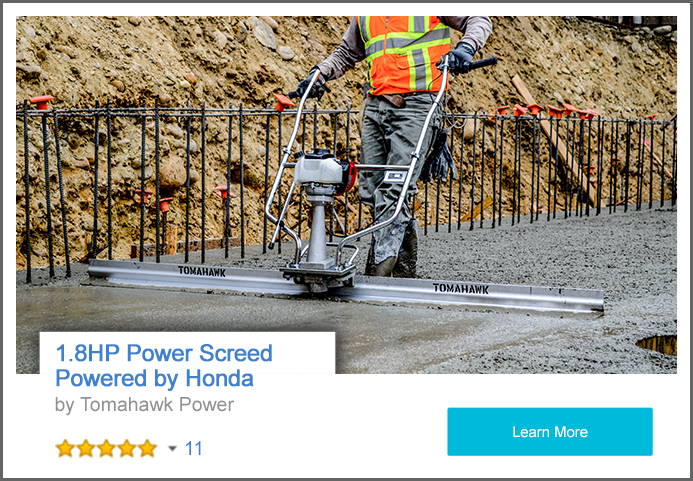

Power screeds, also known as vibrating screeds or strike-offs, are mechanized tools designed to level and finish freshly poured concrete. These tools consist of a vibrating blade that is dragged across the surface of the wet concrete. The vibrations from the blade help to distribute the concrete evenly, remove excess air, and achieve a uniform thickness.

2. Leveling for Uniformity

One of the primary goals of power screeds is to create a level and even surface. A level surface ensures that the concrete is spread evenly, preventing low spots and high spots that can compromise structural integrity and aesthetics. Achieving this uniformity is crucial for projects ranging from floors and pavements to slabs and foundations.

3. Enhancing Compaction

Proper compaction is essential for concrete durability and strength. Power screeds play a vital role in enhancing compaction by removing air pockets and voids from the freshly poured concrete. The vibrations from the screed's blade help to consolidate the concrete, creating a denser and more robust material.

4. Reducing Manual Labor

Before the advent of power screeds, achieving a level concrete surface required extensive manual labor and the use of traditional screeding tools. Power screeds streamline the process by mechanizing the leveling process, reducing the physical effort required and increasing efficiency.

5. Saving Time and Labor Costs

Time is a valuable resource in construction, and power screeds contribute to significant time savings. The rapid and consistent motion of the vibrating blade covers larger areas quickly, reducing the time required to complete concrete placement tasks. This time efficiency translates to cost savings and faster project timelines.

6. Versatility in Applications

Power screeds find application in a variety of concrete placement scenarios. Whether it's a small residential project or a large-scale commercial undertaking, power screeds ensure that the concrete is distributed evenly and consistently, regardless of the project's scale.

7. Ensuring Proper Thickness

Achieving the right thickness of concrete is critical for structural integrity. Power screeds help maintain the desired thickness by spreading the concrete evenly and preventing over-pouring in certain areas. This precision in concrete placement contributes to a more reliable and long-lasting finished product.

8. Ease of Operation

Power screeds are designed for ease of operation. The handlebars and controls are user-friendly, allowing operators to guide the tool smoothly across the concrete surface. This ease of operation ensures that both experienced professionals and those new to the field can achieve consistent and reliable results.

From the moment concrete is poured to the final finishing touches, power screeds play a transformative role in the construction process. By achieving level surfaces, enhancing compaction, and streamlining concrete placement, power screeds contribute to the quality, efficiency, and integrity of construction projects. Their versatility, time-saving benefits, and ability to produce uniformly distributed concrete make them indispensable tools that bridge the gap from pour to perfection in the world of construction.